9/17/2020

Advantages and Disadvantages of Compressors for Pneumatic Operations

Compressors are an essential piece of equipment when it comes to running a pneumatic equipment operation, and there are two types to consider – the Reciprocating Compressor and the Rotary Screw Compressor.

Advantages of the Reciprocating Compressors

- Most Common

Most commonly purchased so there are plenty of mechanics trained to work on - Good Price Point

Lower purchase price

Disadvantages of the Reciprocating Compressor

- Life Span

Shorter life span because pistons, rings, and crank bearings tend to wear out quickly - Takes Up Space

Require a storage tank which takes up more space - Duty Rating

Duty rating is 50% which means it can only make 50% of the air volume and pressure required at any given time - Storage Tank

Storage tank is required to absorb the lack of volume because of the pulse of piston compressed air

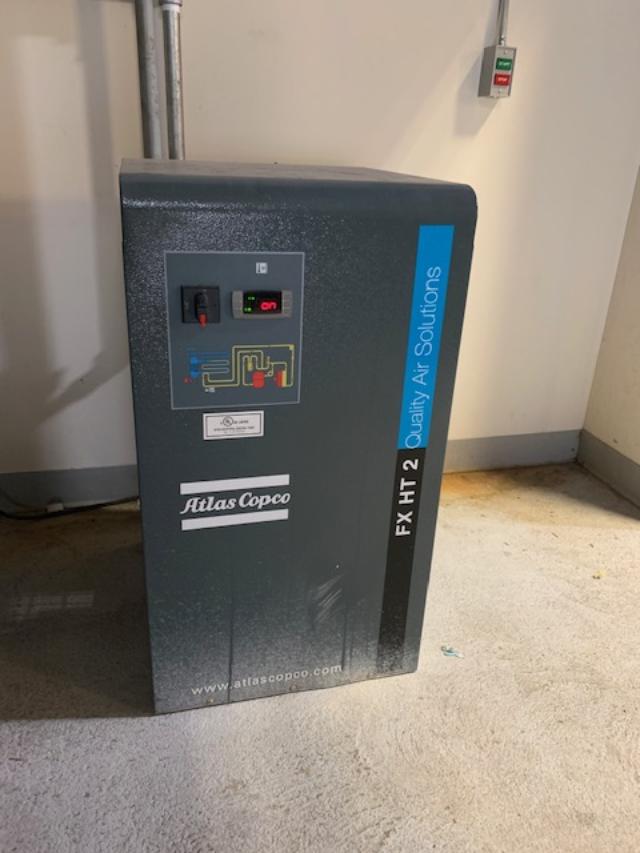

Advantages of the Rotary Screw Compressor

- No Storage Tank

100% duty which means it can run under a load continually and produce the volume needed without a storage tank - Takes Up Less Space

Smaller space requirements thanks to the compact cabinet size and lack of tank - Won’t Wear & Tear as Quickly

Designed so the oil seals the internal rotors preventing wear and tear - Air Volume

Its ability to make steady, even air volume and pressure eliminated the pulse of the Reciprocating design with no storage tank

Disadvantages of the Rotary Screw Compressor

- Price Point

Cost is higher than the Reciprocating Compressor

I guess it is pretty apparent which compressor Tri-State Laundry Equipment Co. prefers. As with most purchases, you get what you pay for, and the Reciprocating Compressor versus Rotary Screw Compressor is no exception. If you are debating which one to choose for your pneumatic operation, let us help you evaluate your options. Simply contact us at 866-885-5218 or check out this link to Atlas Copco Compressors.